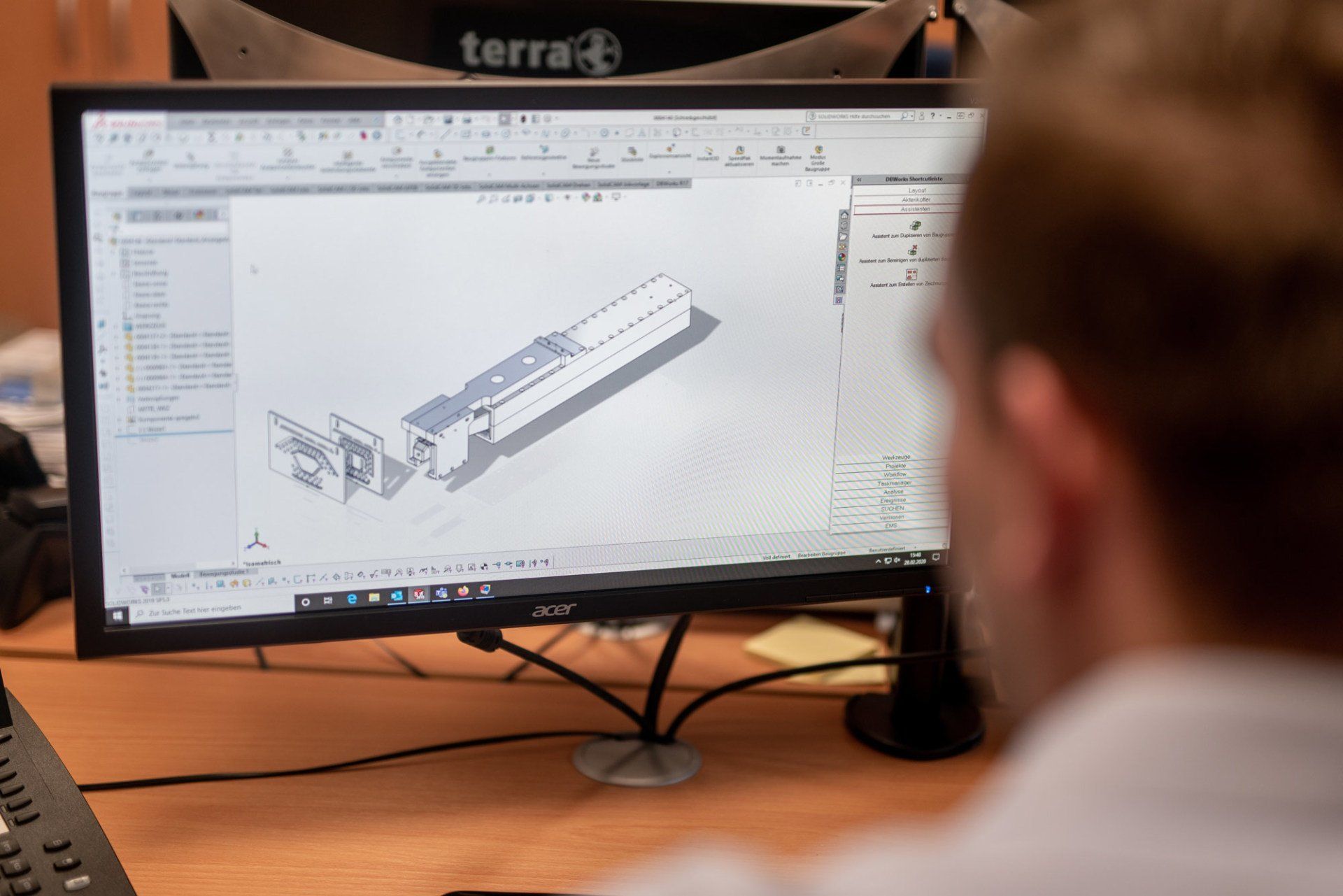

Construction and mechanical engineering by EMS FVK-Profile

A major advantage of our company is a self-contained production workflow. To this end, we have our own design and production department for tool and machine construction with engineers and technical experts for metal technology. You can find technical information about our production here: to our downloads

We can respond flexibly and efficiently to special requests from our customers at short notice. We can develop almost any type and size up to 200x500 mm (HxW) of plastic profiles in a very short time and convert and equip our machines for the production process. Everything regardless of small or large quantities.

Research and quality assurance

We have our own research department with a test laboratory for quality assurance. Here, all specifications for the material and the properties are checked using the latest measurement technology and recognized test series (for stability and load-bearing capacity, flammability, acid resistance and electrical properties, etc.) and documented with all manufacturing criteria.

State-of-the-art production of Emsoplast profiles from Lathen

The Emsoplast profiles are manufactured with specially developed high-performance and precision machines in the pultrusion manufacturing process. In a material process, the basic elements roving (longitudinally oriented glass fibers), fiber mat, resin and aggregates are brought together in a heated molding tool, pulled out of the tool and cut to size under computer control.

State-of-the-art production of Emsoplast profiles from Lathen

The Emsoplast profiles are manufactured with specially developed high-performance and precision machines in the pultrusion manufacturing process. In a material process, the basic elements roving (longitudinally oriented glass fibers), fiber mat, resin and aggregates are brought together in a heated molding tool, pulled out of the tool and cut to size under computer control.

Problem-free reproduction

Depending on the requirements, the type of glass fibers and resins can influence the properties of corrosion resistance, temperature load and other electrical properties, flammability and smoke development.

Due to a complete documentation - from the development over the raw materials as well as the production up to the further processing -, all profiles and every production batch can be completely traced and reproduced.

High performance through 24-hour production

We manufacture a large number of standard and special profiles with widths of up to 500 mm and heights of up to 200 mm. The profile lengths are delivered exactly according to your requirements. There are only limits in the logistical area. Almost all profile types are either available directly from stock or can be manufactured individually for you. We deliver worldwide!

Hermann-Kemper-Str. 19b

49762 Lathen

Fax +49 (0) 5933. 8794-29

OPENING HOURS

Monday - Thursday

8 a.m. - 5 p.m.

Friday

8 a.m. - 4 p.m.